Power transformers are central to reliable power systems, delivering electricity to critical settings ranging from hospitals to renewable energy installations. Specifically, the safe and dependable operation of Vacuum Pressure Impregnated (VPI) and Vacuum Pressure Encapsulated (VPE) transformers is a key component for any facility where ongoing functionality and safety are essential. By following best practices in these areas, facility managers and engineers can protect their equipment and personnel while ensuring undisturbed service. Reliable VPI and VPE Power Transformers are designed explicitly with advanced insulation and robust construction to meet stringent safety standards.

The underlying technology used in VPI and VPE transformers offers substantial benefits for environments prone to high moisture, dust, or service interruptions. Whether installed in industrial plants, hospitals, or renewable energy facilities, these transformers lower lifecycle costs and reduce the risk of fire or electrical failure. The best results are achieved when guidelines on design, manufacturing, and maintenance are followed in detail, maximizing longevity and reliable operation.

One of the most significant reasons for adopting VPI and VPE transformers is their environmental resilience. Since they operate as dry-type transformers and avoid flammable liquids, they are especially suitable for sensitive or regulated environments. This means minimal maintenance, greater safety, and compliance with strict building codes.

Many organizations adopt these transformers for their ability to operate under extreme conditions, from high temperature zones to heavy industrial cycles. This versatility comes from advanced insulation materials and encapsulation techniques that resist moisture and contaminants. By understanding what sets VPI and VPE transformers apart and adhering to best practices, operators gain dependable equipment that minimizes risk and supports mission-critical operations.

Understanding VPI and VPE Transformers

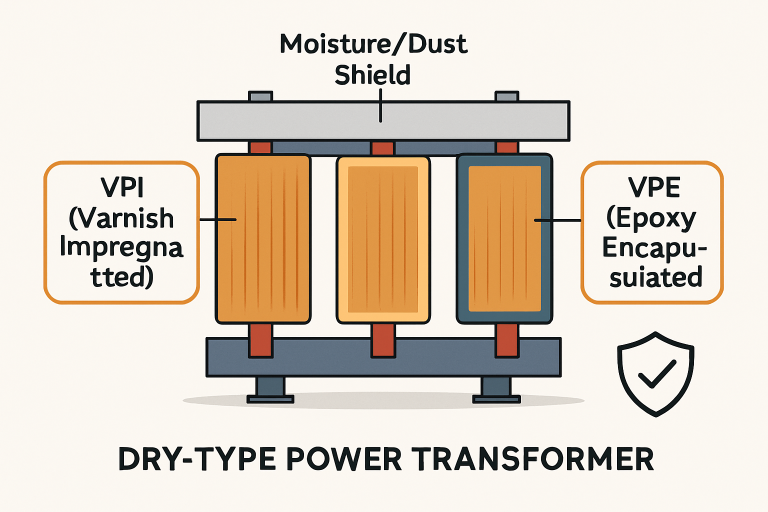

VPI and VPE transformers are dry-type transformers designed for durability and reliability in demanding applications. The VPI process immerses windings in a high-temperature varnish that is pulled deep into the coils under stringent vacuum and pressure. This process ensures complete impregnation, strengthening both the electrical and mechanical aspects. Conversely, the VPE process involves a similar vacuum approach but adds layers of epoxy to the windings, forming a complete encapsulation that enhances contaminant shielding.

These two methods create transformers that are free of traditional oil-cooling risks and environmental hazards, enabling use in high-risk and high-profile locations. Their enhanced resistance to dust, humidity, and corrosive agents means the transformers remain effective for longer periods between maintenance cycles. For safety-conscious sectors such as healthcare, data centers, and public infrastructure, these features deliver peace of mind while keeping operating expenses low.

Design Considerations for Enhanced Performance

Optimizing the design of VPI and VPE transformers ensures they deliver the intended performance throughout their operational life. The insulation material is the first key element in this optimization. Premium materials such as DuPont Nomex, with its high thermal endurance and strength, improve transformer safety by maintaining dielectric strength even in harsh environments. This allows the transformer to function safely in locations where fire resistance is essential, including healthcare and public institutions.

The configuration of the windings is another critical factor in transformer reliability. Winding designs should be chosen for their ability to receive uniform impregnation of varnish or epoxy. This removes the risk of hidden air pockets, which can reduce insulation quality and lead to premature failure. Equally important is the inclusion of robust thermal management features. Efficient heat dissipation not only reduces the risk of overheating but also extends the transformer’s operating lifespan, saving money in the long term.

Beyond these primary design elements, engineers must also consider operational requirements like voltage levels, loading patterns, and fault tolerance. By doing so, they ensure the transformer efficiently adapts to fluctuating demands without compromising performance. For more information on how dry-type transformers are suited to modern electrical demands, visit the CANWIN article on efficiency and reliability of dry-type transformers.

See also: How Technology Innovation Shapes Modern Business Strategy

Manufacturing Processes to Ensure Quality

Quality manufacturing is crucial to ensuring the reliable performance of VPI and VPE transformers throughout their lifecycles. During Vacuum Pressure Impregnation, manufacturers must carefully monitor vacuum and pressure levels to ensure that every winding is thoroughly saturated with the insulating material. Proper impregnation improves heat dissipation and eliminates weak spots where failures could originate.

Quality control during and after manufacturing is vital. Each batch of materials and each production run should undergo detailed inspections to verify the correct properties, such as dielectric strength and thermal resistance. Throughout assembly, process parameters such as curing time and temperature should be tightly controlled to preserve the properties of the insulation and encapsulation layers. These steps help prevent defects that might appear during future operations and ensure uniformity across all manufactured units.

Manufacturers also perform rigorous electrical and mechanical tests following assembly. These tests simulate real-world stresses, confirming transformer resilience before it reaches the customer. This approach is part of a growing industry trend focused on predictive maintenance and reliability, as further discussed in Electric Energy Online’s article on power transformer reliability.

Maintenance Strategies for Long-Term Reliability

After installation, the longevity of VPI and VPE transformers is closely tied to routine maintenance practices. Facility managers should integrate scheduled inspections to catch early signs of insulation or winding degradation. This process often involves power factor testing and resistance measurement, both of which deliver insight into transformer health before issues escalate.

Another maintenance priority is keeping the transformer clean and free from dust or corrosive particles. Dirt accumulation can disrupt heat dissipation, increasing the risk of overheating or electrical discharge. Cleaning should be conducted according to manufacturer recommendations and adapted to site-specific risks.

Finally, advanced diagnostic methods such as partial discharge testing or thermographic analysis can help predict and prevent failures. Using these tools regularly will alert operators to subtle signs of stress or wear, enabling proactive interventions to prevent unexpected downtime.

Applications in Critical Systems

The features built into VPI and VPE transformers make them uniquely valuable across a range of essential industries. In healthcare, they deliver uninterrupted electricity for life-support equipment and diagnostic systems. Their non-flammable design is ideal for confined or indoor spaces, supporting compliance with building and fire codes.

Industrial manufacturing relies on these transformers for continuous control of high-powered machinery. Environments that demand round-the-clock operation benefit significantly from their ability to withstand voltage fluctuations, mechanical stress, and prolonged moderate overloading, while providing reliable protection against environmental contaminants.

As renewable energy capacity expands, VPI and VPE transformers are widely used in solar and wind installations due to their ability to resist moisture and environmental cycling. They provide a key link in distributed energy systems, promoting safe and reliable transmission from the source to end users.

Conclusion

Organizations that prioritize best practices in the design, manufacturing, and upkeep of VPI and VPE power transformers are rewarded with long-lasting, safe, and highly reliable equipment. By selecting proper insulation, carefully monitoring production processes, and committing to ongoing maintenance, it is possible to achieve optimal performance in any application. In sectors where power continuity and safety are non-negotiable, VPI and VPE transformers deliver measurable value for years to come.